Palmer's Brewing Water Adj App

Palmer's Brewing Water Adj App ၏ ရွင္းလင္းခ်က္

The purpose of this application is to help the brewer calculate salt and acid additions to create different brewing waters suitable for particular beer styles. The mineral salts in the water are the seasoning for the beer, and their chemistry sets the stage for the pH of the mash, wort, and beer.

The water chemistry affects the beer flavor in two main ways: seasoning and pH. The water mineral profile affects the flavor balance of the beer (hoppy, balanced, or malty) and also the pH of the beer, and the pH affects how the beer's flavors are expressed to the palate. Lower pH makes the beer flavors brighter, and more attenuated. Higher pH makes the beer flavors softer and rounder.

Suggested mineral profiles are provided for most of the common beer styles. The profiles consist of ranges for calcium, magnesium, total alkalinity as calcium carbonate, sulfate, chloride, sodium, and residual alkalinity. The suggested profiles should combine with the typical grain bill for the style to create a mash pH within the desired range (5.2-5.8 @ 20°C) for good proteolysis and starch conversion. Adjusting the mash pH within that range is a brewer's best tool for controlling the wort pH, and eventual beer pH, for the best beer flavor for that recipe. It all starts with the minerals and residual alkalinity of the water.

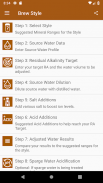

Source water profiles can be saved for future use.

Acid additions to reduce alkalinity and pH are also calculated.

Steps 1-7 assume the entire volume of mash and sparge water is being treated together. Step 8 is for separate sparge water acidification if that water is being treated separately, without salt additions.